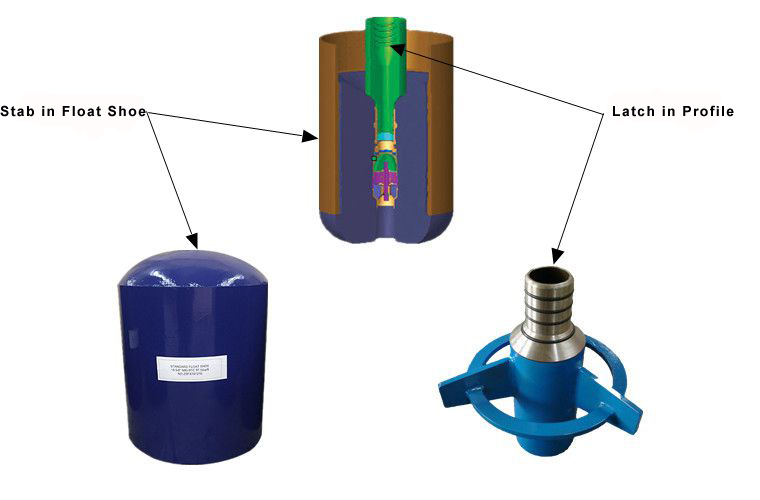

Stab in Cementing Float Collar & Shoe

1.Sizes ranging from 5-1/2″ to 20″

2.Using the stab in seal sub

3.PDC drillable

4.Applying in large large diameter casing

5.Reduce net rig time

Product’s advantage

>>Stab-In cementing is an improved method for cementing large diameter casing.

>>Conventional methods require excessive amounts of cement to ensure cement circulation to surface because of open hole volume, losses

to the formation, or mud displacement efficiency that cannot be determined with sufficient accuracy.

>>In addition, large plugs must be used to separate the cement from the mud and have to be drilled out, along with any cement in the casing.

>>With stab-in cementing, the Drill Pipe is stabbed directly into the Float Shoe or Collar and cement is pumped through the drill pipe until returns reach surface.

>>Cement is then displaced to the bottom of the Drill Pipe — a wiper dart can be used.

>>The drill pipe is then picked up, circulated, and pulled out of the hole.

Feature

>>Improve displacement accuracy —

Cement mixing and pumping continues until cement returns reach surface.

>>Get better cement quality —

The reduced cement/mud interface area and high velocity of flow in the Drill Pipe minimize cement

contamination while the short pumping time eliminates the need for cement retarders.

>>Reduce cement volume —

Conventional displacement requires calculation of excess cement factor.

Whereas with stab-in methods excess cement need be no greater than the volume of the drill pipe.

No large plugs are needed.

>>Reduce net rig time — circulating, pumping, and drill-out times are minimized.

>>Protect casing — cementing pressures are confined to the drill pipe as in a squeeze job.

How to use stab in float collar & shoe with Latch in profile